Stagecraft

The 47 members of the Stagecraft department work with great commitment every day to develop and run the productions of Dutch National Opera & Ballet.

A day in the Stagecraft department

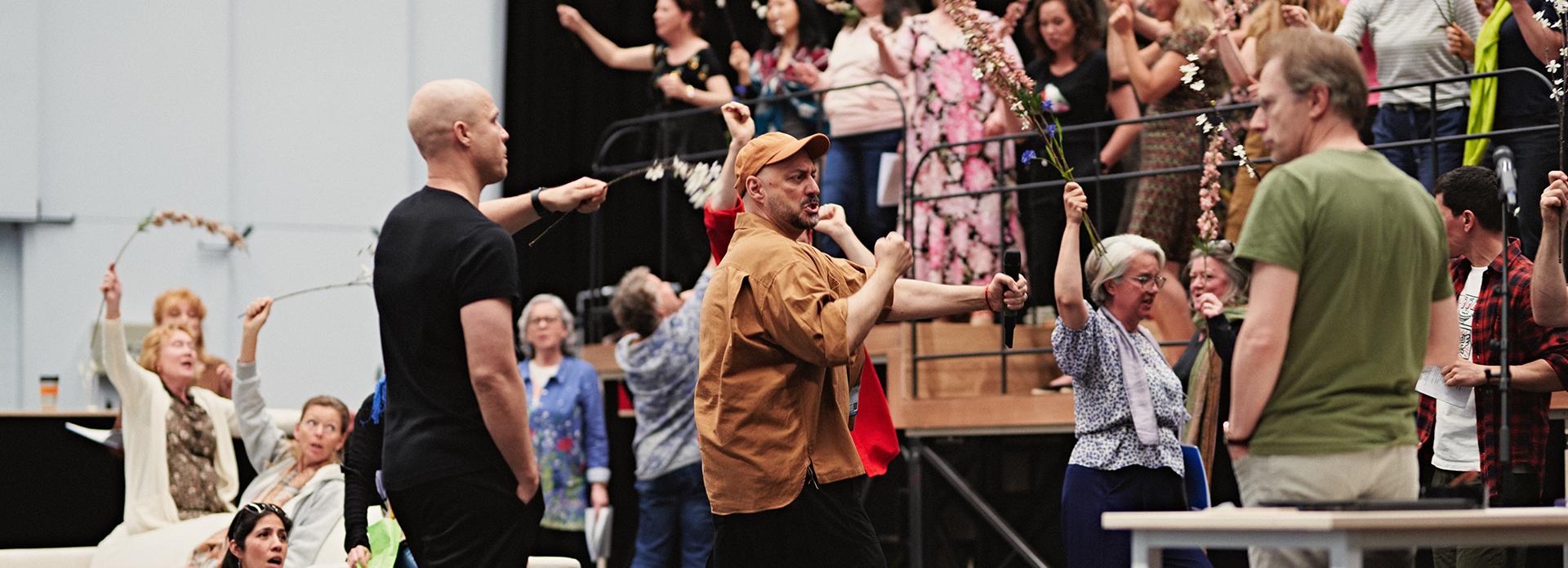

An average day in the Stagecraft department starts at 8am with the construction of a stage set for the day's rehearsals. This set has already been placed on large trolleys or floating floors on the back or rear stage and is ready for use. During rehearsals, the members of the department are responsible for set changes as well as for operating all the theatre’s technical systems.

Plenty of room to manoeuvre

Opera sets can be huge. For an average opera production, the set is transported back and forth on no fewer than six or seven trailers! In order to be able to perform the daily relocation, the team have at their disposal a large rear and side stage – the same size as the real stage – where the various sets can be stored. In addition, there is an assembly hall where the individual set pieces that come out of the truck are put together to make larger components.

Photo: the set of The Sleeping Beauty is 'preset' before the performance | © Liza Kollau

Pulleys, hoists and winches

The team can’t pull this off without all kinds of technical theatre equipment, not only during the assembly and disassembly, but also during the performance.

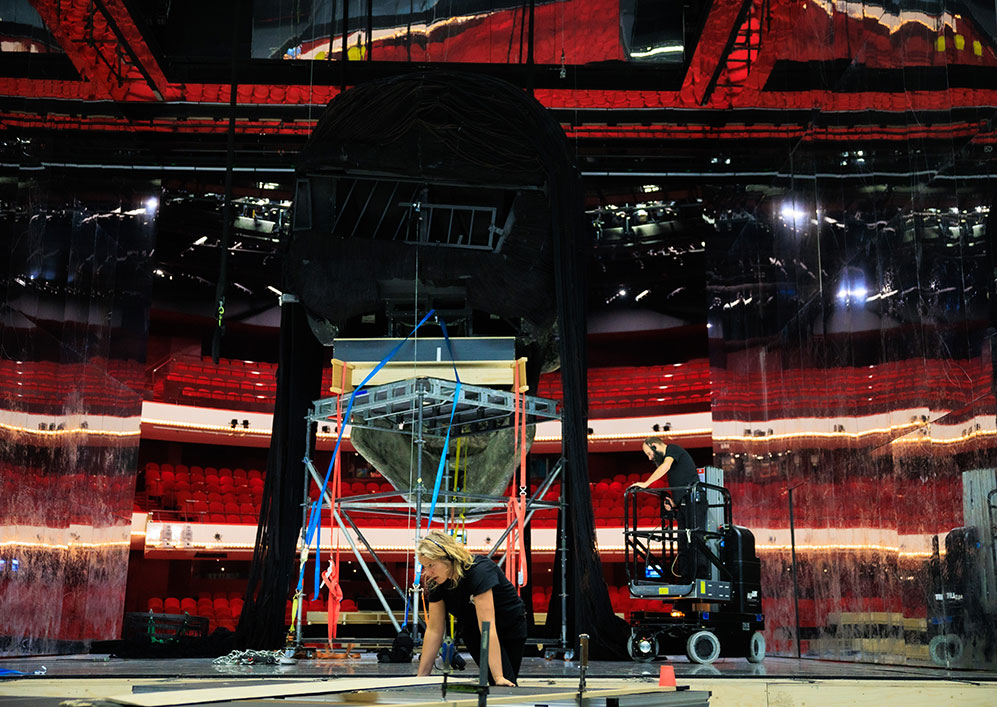

Photo: the ceiling of Turandot is hung in, while the rest of the set is ready to float onto the stage | © Liza Kollau

The team

Comprising 47 members – including carpenters, operators, stage technicians and craftsmen – the team’s daily responsibilities also include preparing and developing new productions and revivals, scheduling work, drawing scenery on stage, and planning logistics.

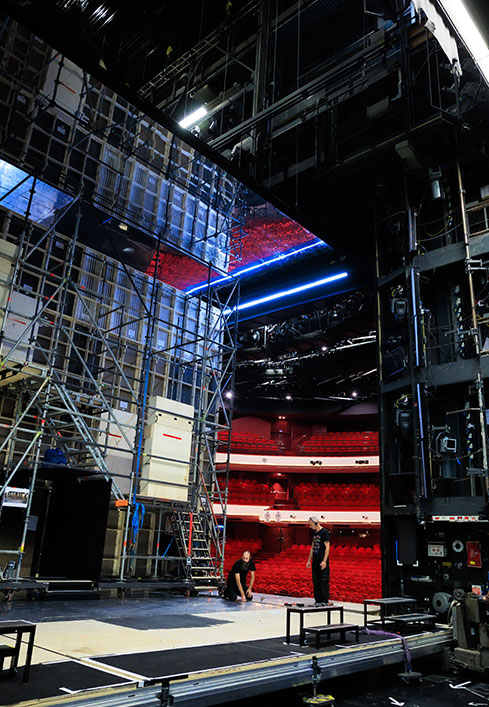

Photo: 2 floor wagons are connected on stage | © Liza Kollau

Did you know ...

Everything runs like clockwork in Stagecraft, with thousands of wheels being set in motion every day!